Description

Tip Spacers Melt Pressure Transducer Shim

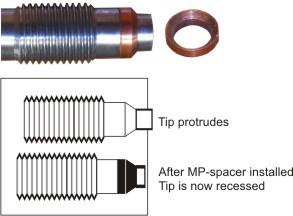

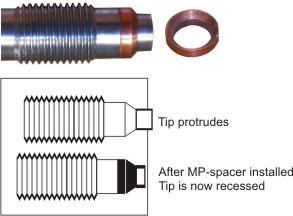

Tip spacers or shims are often used on old extruder barrels where sensor tips are protruding into the melt stream. Transducer tips should be recessed from the inner extruder barrel wall by approximately 0.010”-0.020” to prevent excessive wear and early failure of transducer diaphragms. Our tip spacers / shims essentially push the diaphragm back from the inner wall, as shown in the diagram.

Melt Pressure Transducer Tip Spacer / Shim Features

- Compatible with Dynisco, Gefran, GP50, and other melt pressure transducers and transmitters

- Available in thicknesses from 0.020” to 0.093”

- Material options: copper, brass, stainless steel

Tip Spacer / Shim Transducer

Transducer Spacers or Shims – used on old barrels to help push transducers/rupture disks away from the inner barrel wall.

Note: The melt pressure transducer / transmitter should never stick into the material flow – it should be recessed. This is one of the main reasons for early melt pressure sensor failure.

Features:

- Used to seal push Transducer Tip Back from inner barrel wall

- copper

- Precision Machined

- Sizes 0.025″ to 0.90″

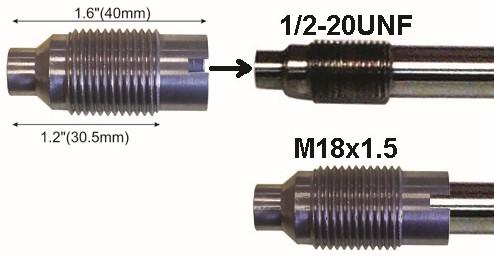

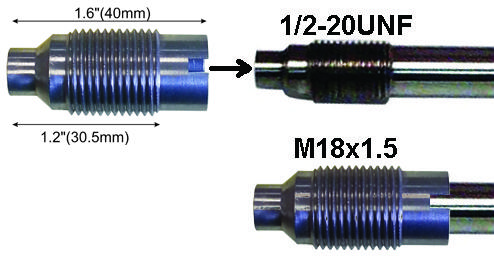

Thread Adaptors: M18x1.5 to ½”-20UNF

Melt Pressure Thread Adaptors – M18x1.5 to ½-20UNF

- Converts M18x1.5 thread to ½”-20UNF standard thread

- Compatible with Dynisco, Gefran, GP50 and other melt pressure transducers and transmitters

- Manufactured from 304/316 stainless steel

Features:

- Emergency Conversion – M18x1.5 to 1/2-20UNF

- 304 SS material

- Precision Machined

High Tech Systems & Equipment Inc. - Systems & Equipment

High Tech Systems & Equipment Inc. - Systems & Equipment