Description

DISCONTINUED

Call for replacements 800-852-8324

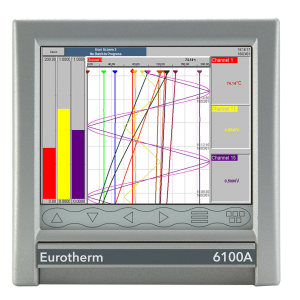

RFS DIN Rail Temperature Controller

- Smart PID tune

- Universal input

- Three outputs

- Logic input

- Soft start power limiter

- Heater failure detection

- EIA485 Modbus

- PC Wizard configuration

IDEAL FOR:

Plastics:

- Extrusion

- Thermoforming

- Injection Molding

Food and beverage:

- Packaging

- Food Processing

Ideal as a slave PID loop to a programmable logic controller the RFS offers a cost effective alternative to performing loops in a PLC while at the same time improving loop performance. All inputs and outputs can be read directly over the Modbus communication interface by the supervisory host system. Additionally, the master can write to RFS outputs that are not assigned as alarm or status functions. This expands the available PLC and host supervisory system I/O, simplifies machine troubleshooting and provides the ability to perform remote diagnostics.

The RFS accepts one universal process input suitable for thermocouple, resistance thermometer or linear mV/mA and coupled with a responsive Smart PID self tuning algorithm it is equipped with special functions including soft start and non-linear cooling. Smart tuning automatically adjusts the PID sets according to the current process dynamics without the need to cycle the process and therefore has no detrimental effect on the current operating conditions.

Three outputs are available providing a heat plus two alarms or heat/cool plus one alarm configuration. A complete set of process protection alarm functions: high and low limit, band and deviation are all included.

Modular interconnection allows simultaneous connection of all common instrument elements: power supply, serial interface, logic input and open collector output for common alarms. Making use of this interconnection the RFS-AL adds alarm expansion capability to RFS loop controllers connected to the same interconnection bus.

High Tech Systems & Equipment Inc. - Systems & Equipment

High Tech Systems & Equipment Inc. - Systems & Equipment